28.03.2022 | Category : spectrum

How does a ratchet actually work?

How does the precision mechanism work?

Every well-stocked toolbox contains at least one ratchet. There is a good reason for this: unlike a screwdriver, a ratchet can be used to tighten fasteners with ease, even in confined spaces.

Definition: what is a ratchet?

In toolmaking, a ratchet or reversible ratchet is a tightening tool that applies torque in one direction only, so there is no load on the fastener in the opposite direction. This allows a fastener to be tightened or loosened by moving the ratchet handle back and forth. The user sets clockwise or anti-clockwise action by means of a change-over lever.

How does the precision mechanism work?

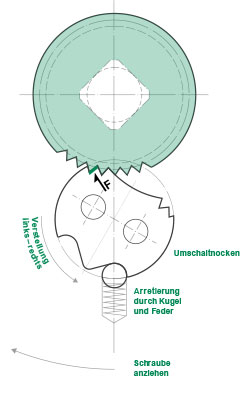

The layout of the mechanism (see graphic):

- By means of two small pins, the change lever shifts the switching cam located beneath it by 30°, in this example, to the left or right.

- A spring-loaded ball holds the switching cam in the respective position.

- The teeth on the square-drive gear and on the switching cam engage with each other (positive locking) and transmit the tightening or loosening torque (M) that results from the rotational effect of a force (F) on a body, please refer to: Spectrum – Torque.

- Note: the more teeth that engage, the better the positive locking effect and the greater the torque that can be achieved.

- If the ratchet is moved in the opposite direction, the teeth of the switching cam become disengaged from those of the square-drive gear. In doing so, they produce the characteristic ratcheting noise. At the same time, the switching cam presses the spring-loaded ball against the spring.

Why are there both normal ratchets and fine-tooth ratchets?

Quite simply, the smaller the pitch between the teeth, the smaller the angle of rotation or ratchet angle until the next engagement – which is the distance by which the ratchet must be moved back and forth in order to further tighten or loosen the fastener.

- Conventional ratchets have a ratchet angle of 10 to 15°.

- However, there are also fine-tooth ratchets that have a ratchet angle of only 4.5°, for example, which enables a particularly sensitive working action.

- There are also freewheel ratchets do not have a detent mechanism at all. They work steplessly.

Does a ratchet require maintenance?

As with every mechanical tool and mechanism, wear and tear will also occur with ratchets. For this reason:

- Make sure you purchase a high-grade tool.

- Lubricate the ratchet regularly using low-viscosity light-running oil.

- Do not overload the ratchet when loosening bolted connections ...

- ... and also keep the ratcheting action smooth and uniform.

- Check the fit of the mechanism and readjust if necessary.

You can see when the teeth are worn because the cover of the mechanism lifts because the teeth are no longer engaging properly. If this is the case, ratchets from many manufacturers can be repaired. STAHLWILLE, for example, offers corresponding repair kits for all its ratchets.